Products

Knitted Mesh

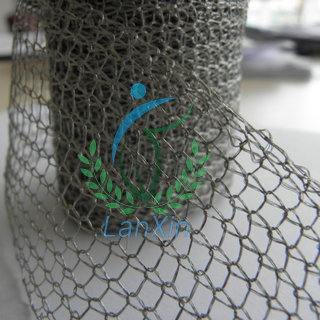

Knitted Wire Mesh, abbreviated as knitted mesh (also known as gas-liquid filter wire mesh, demister wire mesh, gas-liquid wire mesh, foam catching wire mesh, foam breaking wire mesh, knitted wire mesh, woven wire mesh, shielding wire mesh, silencing wire mesh and damping wire mesh), is a kind of wire mesh woven in a special form and the only main element used in the production of wire mesh demister and other separation projects.

Knitted Mesh is widely used. It can be used for oil removal, dust removal and other environmental protection occasions. It is also an important component in sealing, shock absorption (shock absorption), silencing, exhaust purification system and airbag in automobile industry. Shielding devices against electromagnetic interference are also widely used in electronic and electrical products. With the continuous development of industrial level, people have more and more new understanding of the application field and application scope of knitted mesh.

Knitted Mesh Standard:

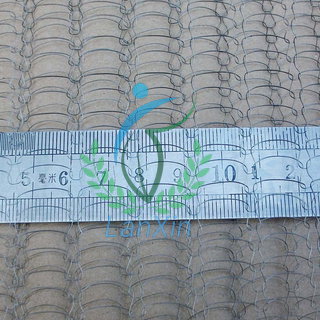

The available wire diameter specification range of knitted mesh is: flat wire or round wire of 0.08mm ~ 0.35mm. It can be single strand weaving, multi strand weaving, mixed weaving of metal wire and non-metal wire (or various fibers), etc. according to the needs of application, it can be rolled into corrugated shapes of various styles and specifications on the screen.

Application Fields of Knitted Mesh:

◆ The Knitted Mesh is used to make the wire mesh demister.

◆ The Knitted Mesh is used for gas-liquid separation, gas-water separation, oil-water separation, dust removal, environmental protection and other filtration devices.

◆ The Knitted Mesh is made into an air filter element on engines such as automobiles and tractors.

◆ The Knitted Mesh is made into sealing, shock absorption (shock absorption), silencing and exhaust purification elements in automobile parts.

◆ The Knitted Mesh is made of high conductivity silk material into an anti electromagnetic interference shielding device for electronic and electrical products.

|

Technical Parameters of Knitted Mesh for HG/T 21618-1998 |

|||

|

Style |

Density kg/m3 |

Surface Area ㎡/m3 |

Void Ratio ε |

|

SP |

168 |

529.6 |

0.9788 |

|

HP |

128 |

403.5 |

0.9839 |

|

DP |

186 |

625.5 |

0.9765 |

|

HR |

134 |

291.6 |

0.9832 |

|

Technical Parameters of SP Style Knitted Mesh |

||||||

| Dia.(mm) | Allowable error in width(mm) | Density ρ(kg/m3) | Surface Area α(㎡/m3) |

Void Ratio ε |

||

| flat wire | round wire | ±20 | 150 | flat wire | round wire | 0.981 |

| 0.1×0.4 | 0.23 | 475 | 320 | |||

|

Technical Parameters of DP Style Knitted Mesh |

||||||

| Dia.(mm) | Allowable error in width(mm) | Density ρ(kg/m3) | Surface Area α(㎡/m3) |

Void Ratio ε |

||

| flat wire | round wire | ±20 | 98 | flat wire | round wire | 0.9875 |

| 0.1×0.4 | 0.23 | 313 | 217 | |||

|

Technical Parameters of DP Style Knitted Mesh |

||||||

| Dia.(mm) | Allowable error in width(mm) | Density ρ(kg/m3) | Surface Area α(㎡/m3) |

Void Ratio ε |

||

| flat wire | round wire | ±20 | 182 | flat wire | round wire | 0.977 |

| 0.1×0.28 | 0.19 | 626 | 484 | |||

|

Materials Commonly Used for Knitted Mesh |

|||

| GB | Other | GB | Other |

| Q235-A | Q235-A | PE | PE |

| 0Cr18Ni9 | 304 | PP | PP |

| 00Cr19Ni10 | 304L | PTFE | PTFE |

| 1Cr18Ni9Ti | 321 | NI | N4、N6、N7、N8 |

| 0Cr19Ni10Ti | 321 | TI | TA2、TA3、TC3、TC4 |

| 0Cr17Ni12Mo2 | 316 | Monel | Monel |

| 0Cr17Ni12Mo2Ti | 316Ti | Hastelloy alloy | Hastelloy alloy |

| 00Cr17Ni14Mo2 | 316L | Inconel | Inconel |

| 0Cr25Ni20Si2 | 310S | ||

| 00Cr20Ni25Mo4.5Cu | 904L | ||

| NS-80 | (1Cr18Ni11Si4AlTi) | ||

| Brass | H65、H68、H62 | ||

| Copper | |||